New study about restraint in industry 4.0 solutions

High implementation costs in the absence of a business case are the main causes of Industry 4.0 restraint

Berlin, March 20, 2015 – Nine out of ten German companies in the implementation of industry 4.0 (Smart Manufacturing) solutions a large storage implementation. Despite a large support from the government as well as research and science Germany is at the forefront in the implementation of the fourth industrial revolution.

New study about restraint in industry 4.0 solutions: Nine out of ten companies have complained the related industry 4.0 high implementation costs of mostly IT-based solutions, which are not profitable ideas. This determines the Berlin based Smartly Solutions GmbH (now Sinfosy GmbH) in a survey of 231 German companies with more than 100 million euros in sales. Although most companies are already using industry 4.0 deal (48%) or want to deal (21%), yet explain the vast majority of these (89%), that often do not expect that from them the projects examined, taking into account the implementation costs.

There are numerous possible industrial projects 4.0 in German companies with high potential for optimization. According to statements of the companies surveyed, 56% more than 5 projects within the company identified that it would be worth it to be processed. 20% of companies see at least 1-5 projects that they would edit.

The range of industrial projects 4.0 is quite broad. 81% see opportunities to optimize maintenance, 41% see approaches to production monitoring, 29% find potentials in logistics (multiple answers possible). The case realizable potentials are according to the survey 57% of cases in the field below 10,000 €, 21% see the savings in the range of up to € 50,000 and only 22% of the saving ideas allow potentials of 100,000 € and more expected.

The study, which was conducted in the period between January and March 2015 nationwide had the goal of the identified reluctance of German companies in the implementation of industrial work up 4.0 solutions scientifically.

The study identifies three main drivers here who can help the company to cancel the implementation of storage solutions for industry 4.0

- Take advantage of partners: industry 4.0 solutions are fast highly complex. Especially small and medium-sized, but also large companies are then overwhelmed when implementing or even fail. So take advantage of partners at the locations where they do not have the knowledge gaps in the company today. This may be a management consultant, the industry show 4.0 potentials or assist in the preparation of business cases. These also include, however implementation partner, build, implement, and can also operate the necessary IT systems. Very important and not available in many companies are big data experts who draw from the data obtained the right conclusions.

- Digitize your products: You can not control what they do not measure. True to their beliefs, it is necessary to digitize their products. These products help to extend forward the value chain. These include not only maintenance services, but it is also possible to optimize logistics chains or to gain important insights for research and development. The investment will pay off.

- Take advantage of the data obtained: Nothing is worse than not to use the data obtained further and broke to leave. This is possible in many different ways and there are several service providers who can help them in this case. Take advantage of the knowledge and let them flow into their products and services.

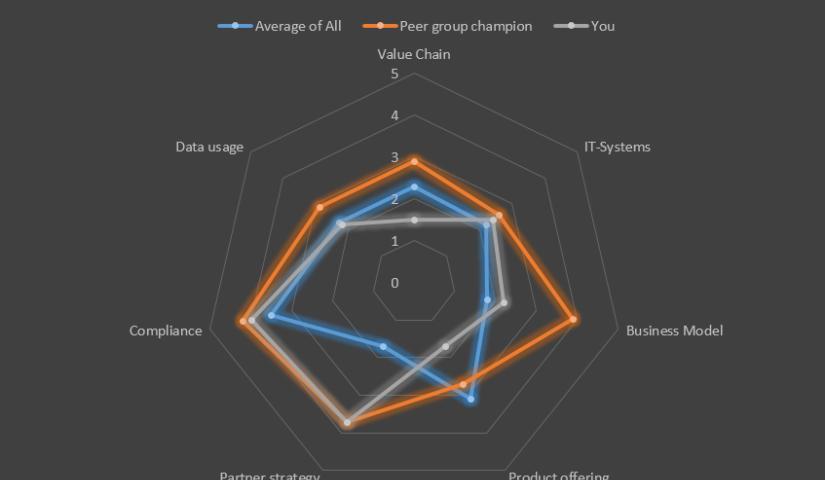

The company Smartly Solutions offers interested companies continue free to make their industry 4.0 strategy to the test. You can find the associated poll here: http://goo.gl/forms/WAvi53Mpa2 As a result, participants will receive a free report that shows its position in the industry 4.0 Maturity Index, and gives recommendations for further improvement.

About Smartly Solutions:

The Smartly Solutions GmbH (now: Sinfosy GmbH) produces and markets innovative industry 4.0 solutions. The wide range of experienced partners from the fields of management consulting, sensor manufacturers, system integrators and Big Data specialists help companies around the world to implement their industrial projects 4.0. Smartly Solutions is headquartered in King Wusterhausen near Berlin.