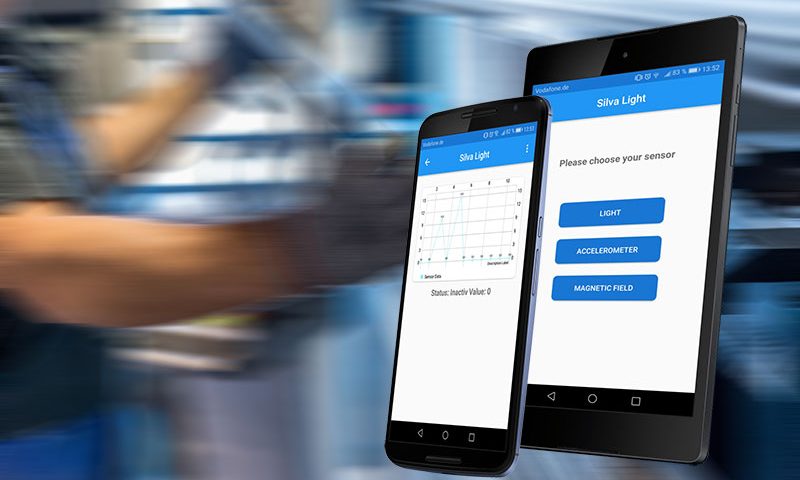

SILVA light – our machine monitoring solution

SILVA light: Mobile machine data logging using mobile phone sensors

Reporting also for older machines

Simple and effective: why using expensive native sensors if there are more cost-effective options. For mobile machine data acquisition SILVA light, Sinfosy relies on the standard sensors installed in commercially available smartphones.

“We use the best-tested sensor technology – and these are the mobile phone sensors,” explains Dr. Karsten Königstein, Managing Director of Sinfosy GmbH. “Depending on the use case, SILVA light offers a variety of options for monitoring machines, including remote diagnosis.” Several sensors can easily be used simultaneously for machine monitoring.

For example, the acceleration sensor measures the smallest movements on the machine: does the machine run or does it even run non-circularly? Parts that fall into a designated basket can also be counted. The light sensor also opens up the possibility of counting the number of parts produced or precisely recording welding times. SILVA light also informs whether components or devices on the machine are open. The magnetic field sensor measures the current flow of the machine quickly and easily, i.e. it indicates whether the machine is operating or has failed.

“SILVA light is particularly suitable for older machines that do not yet have sensors or for newer machines that are only equipped with expensive interfaces,” explains Dr. Königstein. This means that the smartphone camera can also read out analog meters at any desired interval. Many older machines have drag counters, whose values are then digitally recorded.

The collected data can be processed and evaluated via the SILVA light app. Depending on the requirements, the data is encrypted and backed up in the cloud or in a file. The data can be further processed in other programs via the.csv exchange format. If predefined reporting points are reached, the system informs by push message. For example, if a machine stops, maintenance receives a message immediately and can react accordingly.

In combination with the STPS system from Sinfosy, all data can be visualized in the control station or in the production cell without great effort. STPS provides all data required for production clearly arranged on smartphones, tablets or monitors.

As with all products, Sinfosy offers SILVA light as System-as-a-Service (SaaS). Sinfosy provides customers with the necessary software and hardware as a service and also takes over the service. The system can be implemented quickly and easily on site; the customer’s IT resources are not used. Customers only pay a monthly fee, which depends on the scope of the respective use case and the agreed support time (from eight hours on weekdays to 24/7 all-round service).

Contact person for editors:

Evgeniia Sentsova

Teamlead Marketing

T: 03375-917 9071

M: ese@sinfosy.com